Attendance:

59 members, 2 guests, and 3 new members.

NEWS

Roy Wall, Guild President, welcomed everyone to the meeting and highlighted the technological advancements adopted over the past five years since the onset of COVID-19. Several members appreciated the leadership’s efforts to keep the guild engaged throughout the pandemic.

Phil Morgan, Guild Vice President, announced this year’s theme as “A Deeper Dive in 25.” Members are challenged to enhance their projects by increasing difficulty or trying new techniques.

Upcoming Challenges

- February: Heartwood Gifts – Create a gift for someone you love.

- March: 2X4 Showdown – Construct something using only one 8-foot 2×4.

- April: Buddy Build – Pair up with a guild member who has a skill you’re interested in and build a project together.

Reminders

- Dues: A number of members have not yet paid their 2025 dues, which remain at $20.00.

- Photos: Nearly 40 members still need to have their photos taken for uploading to the online directory.

Phil’s Finds

Highlighted tool: 2-Piece Dual Head Nail Setter and Hinge Pin Punch Set featuring a spring-loaded design, heat-treat hardened steel, and delivering up to 5000 PSI of striking force without a hammer.

How To in 2

Larry McFerrin was the first guild member to work with the leadership team to produce the first in a new video series the Guild call How to in 2. These are intended to be short (in 2 minutes or less) informational videos to demonstrate how the members perform some type of woodworking tasks that makes their projects easier to complete. Larry demonstrated how to make a simple jig for routing out mortises for butt hinges. Video can be viewed here.

Program

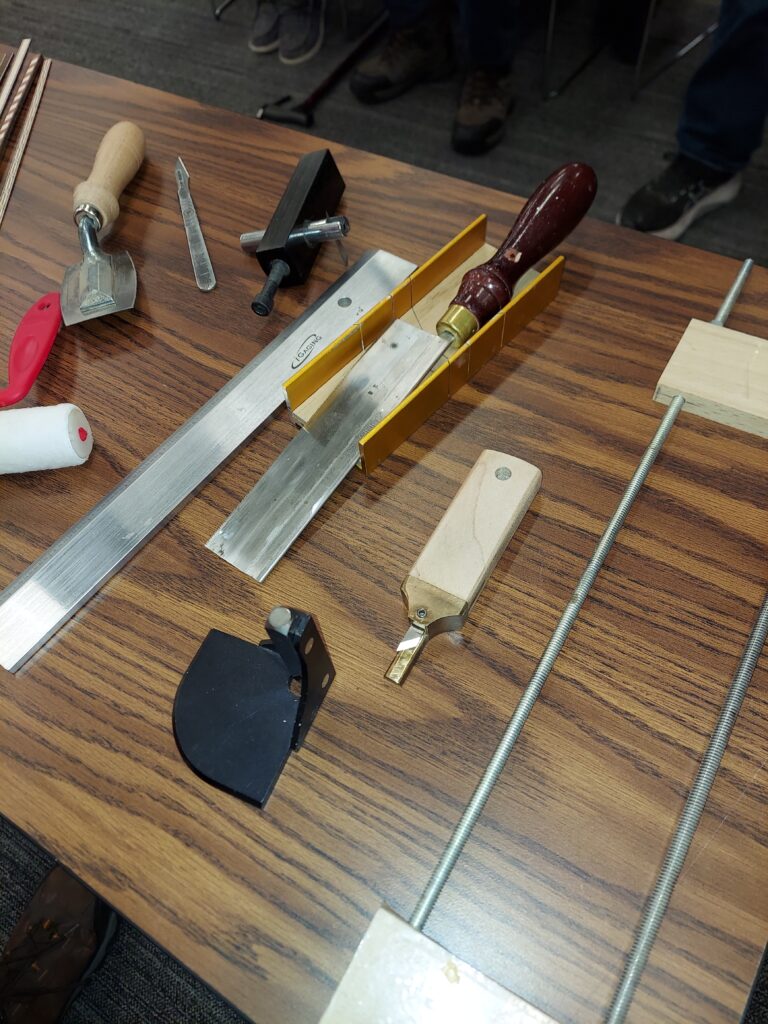

David Clark presented on creating custom banding. He emphasized that while pre-made banding is available at stores such as Rockler and Woodcraft, creating your own allows for unique designs and larger widths.

He still purchases the raw materials from the wood working stores, but by making it himself he is able to create unique designs and much larger widths of banding that better meet his needs for whatever his project is.

David went over the tools he uses to create each piece and how he assembles the raw blanks that will be cut into banding. The most common thickness he uses is 1/42 of an inch, super thin! Some of the tools he highly recommends having in order to cut your own banding is a slicing gauge, cutting matt, veneer saw, a good sharp knife and a metal straight edge.

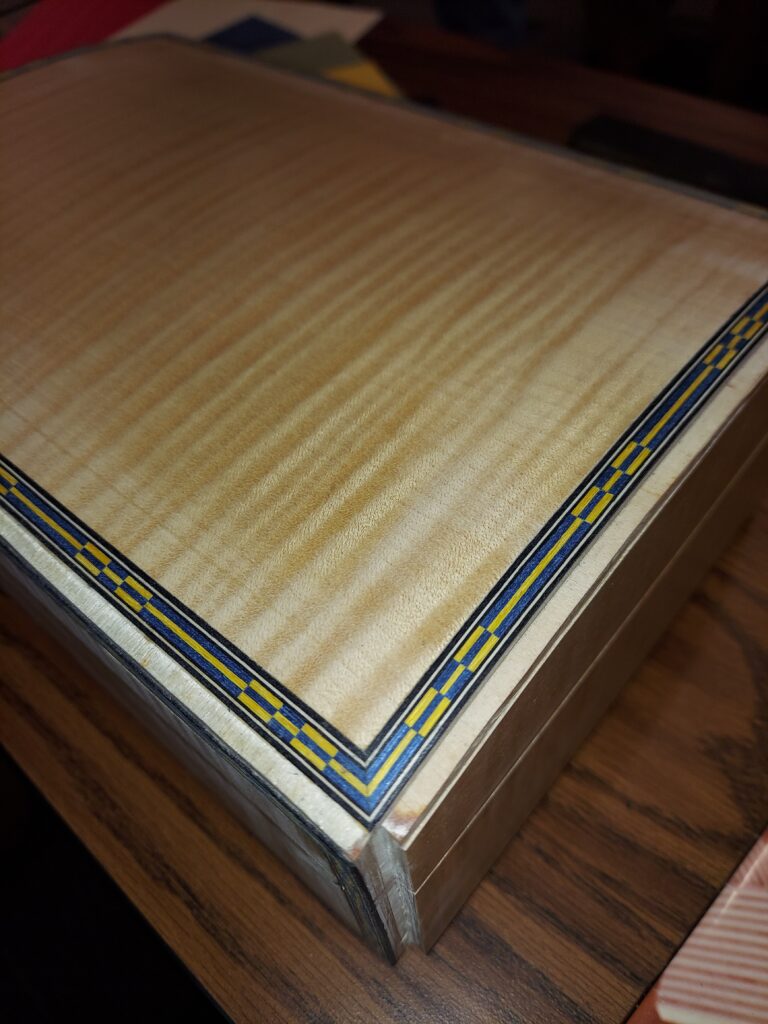

David brought in the box to the right, a work in progress, to show the detail that goes into each box that he creates. Thank you, David, for an awesome presentation.

Average Rating