NEWS

Roy Wall, Guild President, opened the meeting by welcoming everyone and recognizing the visitors. Roy also thanked all the members who assisted with the CHARM shop sale and who purchased tools and other items. Due to the team effort, we were able to assist Mr. Bibbee in collecting enough proceeds to purchase 6 bicycles for the Wrestling MS National Cycling Team.

We had a good turn out this month with 56 members signing in and six visitors for a total attendance of 62 people.

Dues – John Freeland announced that as of the September meeting we are now accepting dues for 2025.

Jim Mullen presented to the attendees on why you should have a torniquet in your safety kit and how to apply it. He pointed out that, statistically, there is a table saw accident every 9 minutes in the US and having a torniquet can save your life. Most of us are working in our shops alone and if there is an accident we are not going to have immediate help. We need to know what to do and fast. Knowing how to apply a torniquet by yourself, even one handed, could be the difference between you just having a serious injury or something much worse.

PHIL’S FINDS

Phil brought in the Tesman TM-510 Smart Digital Multimeter. Thanks to its Smart Auto Mode, TESMEN TM-510 4000 counts smart digital multimeter allows you to quickly switch between all measurement tasks, including AC/DC voltage, resistance, and continuity, without selecting a mode or range. It makes measuring work easy, fast, and accurate. He found it on Amazon for under $15.00. Nice find.

PRESENTATION

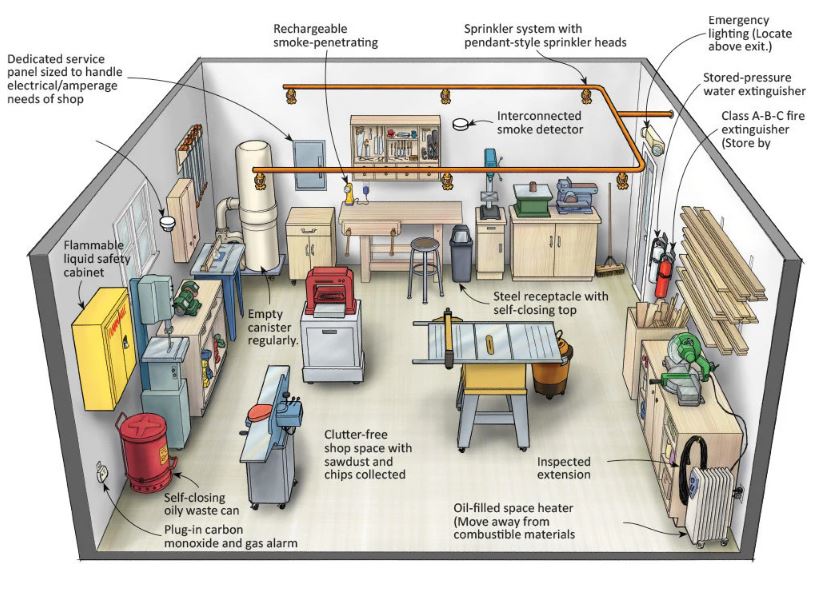

Mr. Rob McQueen from the Lee’s Summit Fire Department came to the Guild meeting and presented information and recommendations on how to keep your home shop safe. In his many years with the Fire Department, he has witnessed many preventable accidents had there been just a little attention paid to safety.

The number one recommendation, which should be obvious, but isn’t always, is know your shop. Know exactly where your emergency kit is, where your fire extinguisher is, where the circuit breaker is and which breaker controls what specific outlet. When an accident happens, there is often no time to go hunting around the shop for where you placed your emergency kit or your fire extinguisher. (Image curtesy of Woodcraft)

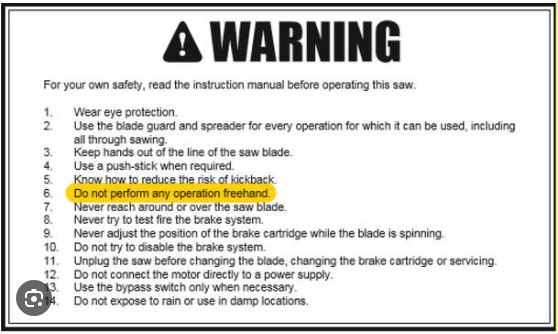

The next recommendation is to read and understand the instructions that come with your tools. Tools, especially power tools, are not always as straight forward as they should be and trying to figure how to use it when it’s plugged in is an unnecessary opportunity for an accident to happen.

Third recommendation is to always use your safety equipment. This isn’t limited to safety glasses, hearing protection and gloves, but the blade shields and other safety features that come with your saws. Those safety items that sometimes get removed or disabled because they are “inconvenient”.

Rob’s fourth recommendation is to have proper lighting in your shop. Being able to see your work know exactly where your work piece is in relation to cutting edge of the tool your using not only improved the accuracy of your cut but also ensures your cutting where you think you are and not your fingers.

The fifth recommendation is the ensure the layout of your shop has an easy flow and reduces to the greatest extent possible all tripping hazards. If you need to run an extension cord across the floor in order to get power to a specific tool then be sure to incase the cord in a floor cord protector that is specifically design for that purpose.

Rob’s sixth recommendation was about using the correct size and gauge of extension cord and to not daisy chain power strips. Using under sized power cords and daisy chaining power strips is one of the leading causes of fires and easily preventable just by using the right gauge of extension cord.

Rob presented a video on how combustible saw dust is which drove the point home that we need to keep our shops clean before, during, and after we are working on a project. The dust we create that is in the air and lands on every surface can be a flash point that can lead to serious damage. Doing things like leaving oily rags wadded up in the corner is a sure way to have a spontaneous combustion incident that will be significantly aided by the saw dust laying around your shop.

Finally, Rob talked to us about fire extinguishers and that they must be stirred at a bare minimum of once per year. You do this by just turning it over on its top a few times. This is critical due to over time the powder separates from the propellant and then is useless when you need it. Additionally, fire extinguishers need to be replaced about every 10 years, regardless of whether the gauge says it still fully charged.

SHOW & TELL

This month’s show and tell was all about taking scraps from one project and using them to create something else. Scrap Savy September! In this example Phil Morgan took the left-over pieces from the tulip ring bowl in the top right to make a tulip ring lid for the vessel lower left.

He then took the remainder of that and made a handle for a beautiful box.

The rest of this month’s show and tell can be viewed in the Gallery HERE.

Average Rating